How to Perform a Structural Assessment

Posted 2 years ago in TECHNOLOGY.PC Onsite helps businesses to choose the best solutions, set up, configure, operate and support the IT system for Auckland businesses.

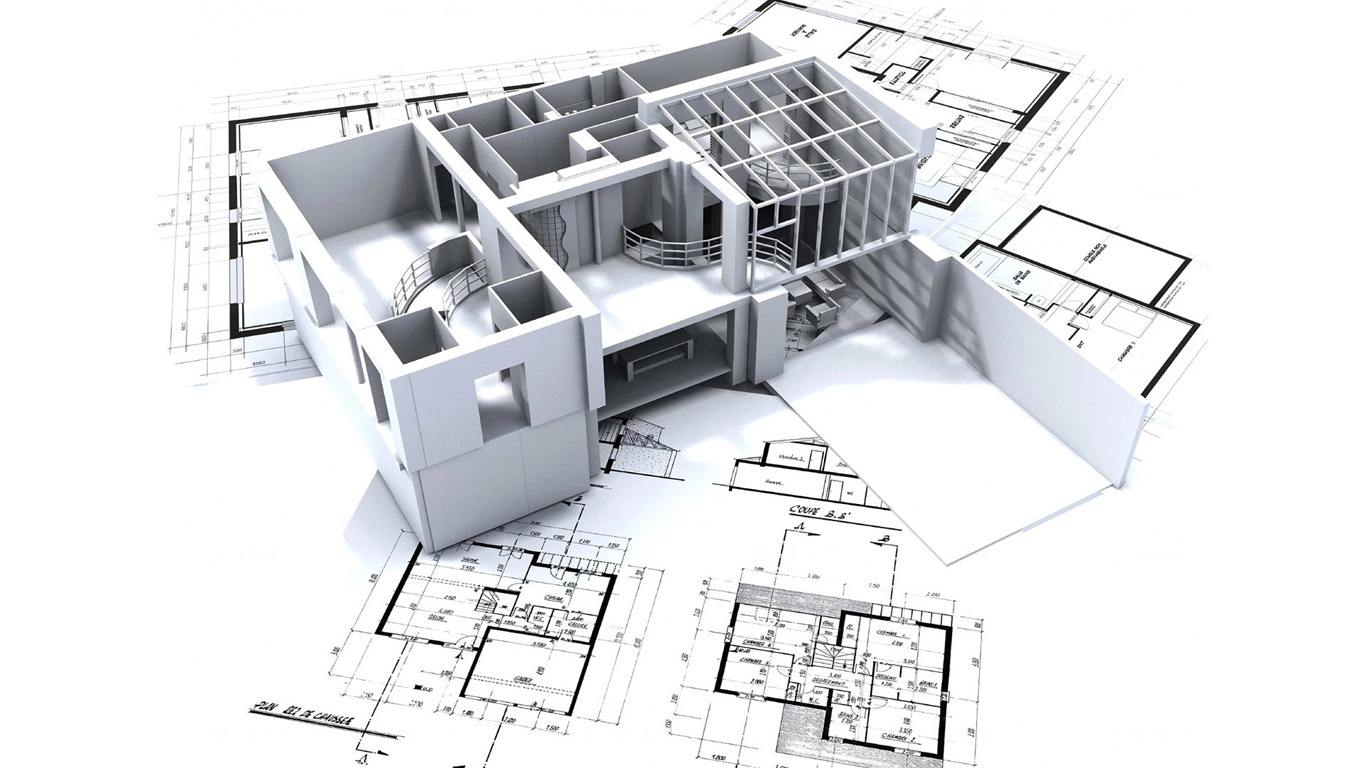

The process of structural assessment involves inspecting structures for damage and defects. This can be done using Non-destructive testing and Failure Assessment Diagram (FAD). Continuum solid element models can also be used to analyze structural health. If you are involved in the structural assessment process, read this article to learn more. Here are some common questions and answers. If you have any questions, feel free to contact us. We will be more than happy to answer any questions you may have.

Inspection of a structure

The Department of Transportation (DOT) encourages the inspection of structures and other infrastructure as part of its maintenance program. However, some unusual events may affect structures. Depending on the nature of the problem, an inspection is necessary as soon as possible. The District Structures Maintenance Engineer (DSME) will prioritize inspections by traffic levels and susceptibility to damage. The following are some examples of situations where an inspection is necessary. Listed below are a few of the most common scenarios for a structural inspection.

When completing an inspection, the inspector must carefully evaluate the overall structural system of the structure. Inspecting the foundation, floors, walls, columns, ceilings, and roof are among the things a structural engineer must check. They must also consider any above-grade vegetation. Moreover, they must not perform any job functions that are illegal. Once they complete the inspection, they will then provide a detailed report that will include recommendations.

Failure assessment diagram (FAD)

A failure assessment diagram (FAD) is a useful tool for assessing the safety of a component. Also known as a two-criteria method, it covers failure due to brittle fracture and plastic overloading. The failure assessment line represents the interaction between the two modes of failure, and points within the FAD are considered safe and those outside are potentially unsafe. The FAD can be helpful in determining the safety of components that are not designed for repeated use.

A FAD uses a two-parameter approach to failure analysis, accounting for the plasticity of a material near the failure locus. Its failure locus is shown in red, along with material-specific failure statistics. The FAD can also be used to determine the yield strength and plane-strain fracture toughness of a material. The FAD is a useful tool for failure analysis because it can account for material plasticity and other variables that can influence a failure.

Non-destructive testing

Non-destructive testing has numerous benefits and is often a necessary part of periodic structural inspections. The main objective of the process is to determine the structural capacity of a building or structure. In addition to ensuring maximum structural capacity, it also minimizes local damage that may be detrimental to the building or structure. This type of testing is often complementary to other tests, such as Ultrasonic Tomography and GPR scanning.

Non-destructive testing uses various non-destructive inspection methods to measure the properties of materials and structures without causing physical damage. It is the most effective way to evaluate a structure, component, or entire building without risking damage or removing it. The advantages of NDT methods outweigh the time and cost of using destructive tests. Below is a brief overview of the most common methods used in structural assessment:

Continuum solid element models

A comparison of finite element and continuum model methods shows that the latter is more accurate in interpreting local failure, but that the former incurs higher computational costs. However, these models can be partially replaced by numerical simulations in certain cases. Continuum solid element models can be used to analyze the structural behavior of buildings, and they are a good choice for seismic and wind loading analyses. But, before making a final decision, consider the pros and cons of each.

One of the biggest differences between the two methods is the use of higher-order Fourier terms. A standard 3-D solid element model interpolates displacements piecewise, while a continuum model solves contact and localized deformation problems by introducing higher-order Fourier terms. For axisymmetric elements, the use of torsion can help minimize contact stresses. But, if you're using a continuum model for structural assessment, you'll still have to understand how it works.

Cost of a structural assessment

Performing a structural assessment of a home can cost between $300 and $700. The engineer will look at the foundation, joists, beams, and load-bearing walls to determine whether or not there are any problems. If a problem is found, the structural engineer will offer his or her expert opinion in the post-inspection report. A structural assessment may also reveal structural defects that you may not know about.

The cost of a structural assessment depends on several factors, such as the amount of time the engineer will need to complete the project. A structural engineer's time will likely be an hourly rate, which means the total cost will vary. For example, if you are remodeling a house and need to determine if a wall is supporting the structure, a structural engineer will charge anywhere from $150 to $300 per hour. In addition to the cost of the structural assessment, a structural engineer will also draw up a plan for replacing the wall.